This text offers a comprehensive overview of standard shipping container sizes (20ft, 40ft) and their uses in international trade and innovative solutions. Vertical stacking, leveraging containers' uniform dimensions, maximizes space utilization for cargo storage and transportation, especially in areas with limited floor space or tall items. Safety considerations include weight distribution, structural integrity, and securing containers during transport. Consulting region-specific shipping container dimension guides ensures compliance with best practices and local regulations, crucial for efficient logistics management.

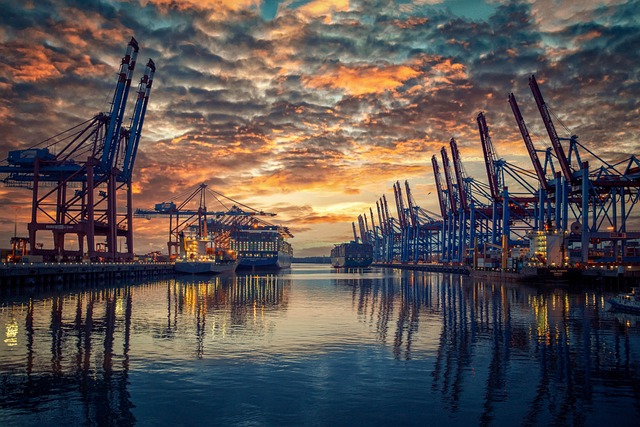

In today’s globalized logistics landscape, understanding shipping container dimensions is paramount for maximizing space utilization. This article delves into the intricacies of tall shipping container dimensions, focusing on their extra vertical stacking capabilities. We’ll explore standard container sizes, the art of vertical stacking, factors influencing stacking height, and the numerous advantages of adopting tall containers for efficient storage. Safety considerations will also be addressed to ensure responsible handling in these densely packed environments.

- Understanding Standard Shipping Container Sizes

- Vertical Stacking: Maximizing Space Utilization

- Factors Affecting Container Stacking Height

- Advantages of Tall Containers for Efficient Storage

- Safety Considerations for Stacking and Handling

Understanding Standard Shipping Container Sizes

Vertical Stacking: Maximizing Space Utilization

Vertical stacking is a game-changer when it comes to maximizing space utilization in storage and transportation using shipping containers. By carefully considering the dimensions of these standard ISO containers, particularly their height, it becomes possible to stack them one on top of another, creating additional vertical space for more efficient cargo loading and organization. This technique is especially beneficial in areas with limited floor space or when handling tall and bulky items that require elevated storage solutions.

The key to successful vertical stacking lies in the shipping container dimensions. The standard 20ft and 40ft containers have specific internal dimensions that allow for a certain degree of flexibility in stacking. For instance, the 20ft high cube container offers ample headroom with its external dimensions of 20′ x 8′ x 8.5′ (L x W x H) and internal dimensions of 19’7″ x 7’8″ x 8’3″ (L x W x H). Similarly, the 40ft high cube container provides even more space with its larger external measurements of 40′ x 8′ x 8.5′ (L x W x H) and internal dimensions of 39’7″ x 7’8″ x 8’3″ (L x W x H). Understanding these shipping container door opening dimensions, floor, ceiling, and overall footprint is crucial when designing a layout that facilitates vertical stacking, ensuring both safety and stability.

Factors Affecting Container Stacking Height

When considering the vertical stacking capabilities of shipping containers, several factors come into play that dictate how high they can be stacked safely. The primary considerations include the shipping container dimensions, specifically their height, width, and length. Standard ISO containers, for instance, have standard container dimensions with heights ranging from 2.13 meters (7 feet) to 2.64 meters (8.7 feet), depending on the type. Within this range, factors like shipping container door opening dimensions, floor dimensions, and ceiling height must be taken into account to ensure stable stacking.

Furthermore, the internal dimensions of a shipping container, such as the 20ft container internal dimensions or 40ft container internal dimensions, impact the amount of space available for goods when stacked. Containers like high cube containers offer enhanced vertical space due to their high cube container dimensions. Conversely, narrow and wide shipping container dimensions, reefer containers, flat rack containers, open top containers, modular containers, and custom containers have varying stacking considerations due to their unique designs and internal features. It’s crucial to refer to a shipping container size chart or shipping container dimension guide to understand the precise tolerances and dimensions, ensuring safe and efficient vertical stacking based on these key factors.

Advantages of Tall Containers for Efficient Storage

The advantages of tall, vertical shipping containers are multifaceted when it comes to efficient storage and logistics. One of the primary benefits is their height, which allows for maximum utilization of vertical space in warehouses, distribution centers, and ports. This stacking capability means more goods can be stored in a smaller footprint, leading to optimized space use and cost savings. With dimensions like 20ft or 40ft shipping container sizes, these containers offer flexible and scalable storage solutions.

Additionally, tall containers have internal dimensions that cater to diverse cargo needs. Whether it’s standard ISO container measurements or specific requirements for reefer, flat rack, open top, or modular containers, the internal dimensions of these tall units accommodate a wide range of cargo types and sizes. This versatility ensures they are suitable for various industries and applications, making them a game-changer in modern supply chain management.

Safety Considerations for Stacking and Handling

When stacking shipping containers for vertical storage or transport, safety should always be the top priority. With proper handling and adherence to industry standards, it is possible to maximize space while ensuring the integrity of the structure. Factors such as weight distribution, center of gravity, and structural strength are critical considerations. Containers must be securely fastened together using appropriate lashing equipment to prevent shifting during movement or in the event of extreme weather conditions.

The dimensions of shipping containers play a significant role in safety. For example, 20ft and 40ft shipping container dimensions dictate the maximum weight capacity and space requirements for stacking. High cube containers offer increased internal height without altering the standard external dimensions (ISO container dimensions), allowing for more efficient loading while maintaining safe stackable dimensions. It’s essential to consult a shipping container dimension guide (including floor, ceiling height, and door opening dimensions) specific to your region to ensure compliance with local regulations and best practices.

In conclusion, understanding the tall shipping container dimensions and their enhanced vertical stacking capabilities is paramount in optimizing space utilization. These containers offer significant advantages for efficient storage, especially in compact or high-density environments. However, it’s crucial to consider factors affecting stacking height and prioritize safety measures during handling and stacking to avoid potential risks. By leveraging these innovative solutions, businesses can revolutionize their logistics and storage strategies, ensuring cost-effectiveness and streamlined operations.